VIBRATORY SYSTEMS SOLUTIONS IN AUSTRALIA

Material Flow Solutions

With years of experience in the industry, we provide a wide variety of solutions to help deal with all your material flow and transportation problems. Our expert team can help to refine and optimise your production processes for more effective and efficient results

VSS Supplies Solutions For:

- Relieving product obstructions

- Avoiding bridging and rat-holing

- Feeding small parts

- Loosening stubborn adhesions

- Maintaining product flow

- Reducing lumps in bulk materials

- Compaction of bulker bags

- Driving feeders and conveyors

- Avoiding clogging

- Sieving bulk materials

- Compacting moulding sand

- Stress relieving small parts

- Testing components

- Feeding small quantities

- Conveying raw material

- Filling containers

- Knocking off sticky material

- Cleaning filters

- Spreading bulk material

- Concrete compaction

- De-moulding foundry parts

Flow Aids & More

What Are Flow Aids?

A flow aid is the generic term used for any device that promotes flow from hoppers and down chutes. At VSS, we have many years’ experience supplying vibrators for this purpose, ranging from a gentle action to more forceful options.

How Can A Flow Aid Help Me?

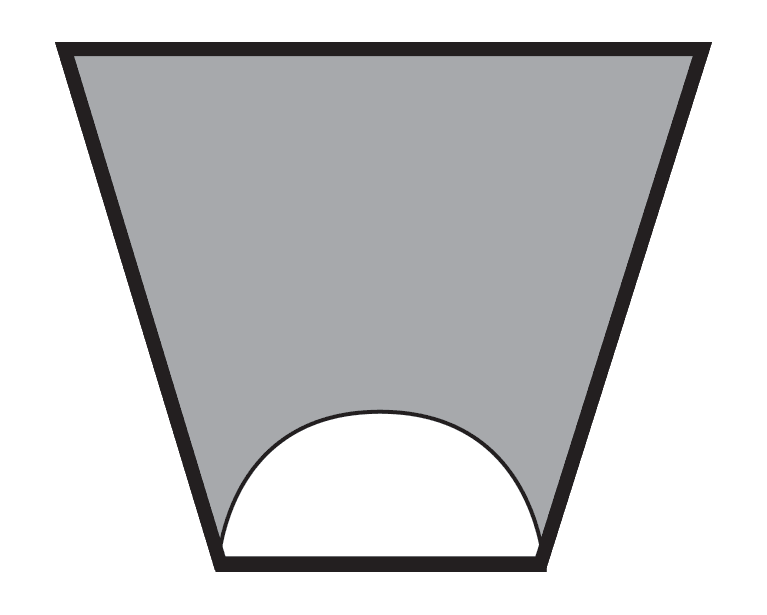

The usual problems on production lines are caused by the product sticking to the hopper walls, bridging over the hopper outlet, or sticking to itself, with only the product directly over the outlet discharging. Our experienced team can diagnose the issues within your system to provide a vibrator solution that’s tailored to your specific needs, getting your product moving again.

Which System is Right For Me?

The rule of thumb is that fine, dry materials will need a high frequency, low amplitude vibration while coarser products usually respond better to low-frequency vibration. In all cases, we are trying to vibrate the product, not the hopper.

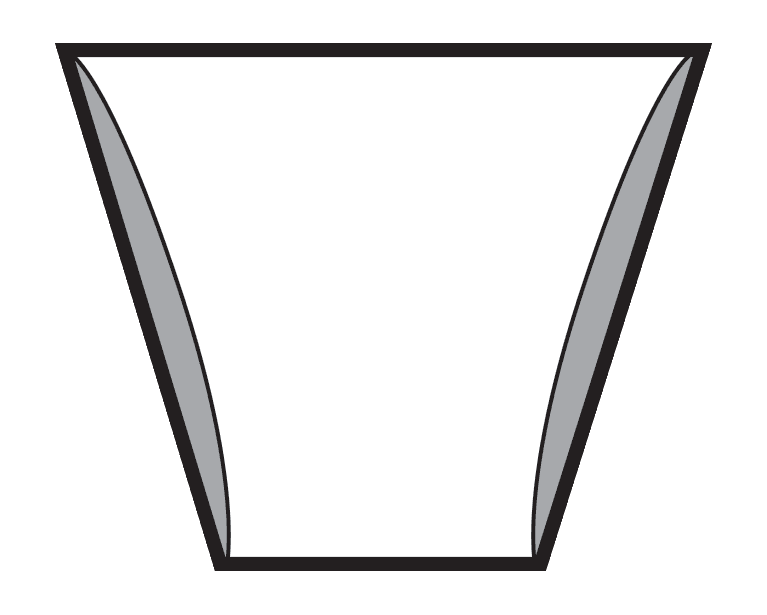

Fine/dry Product

Rotary models are most often used on fine dry materials, as these materials often only need gentle vibration to make them flow. Larger particles over 40mm may need more amplitude and lower frequency.

Clinging

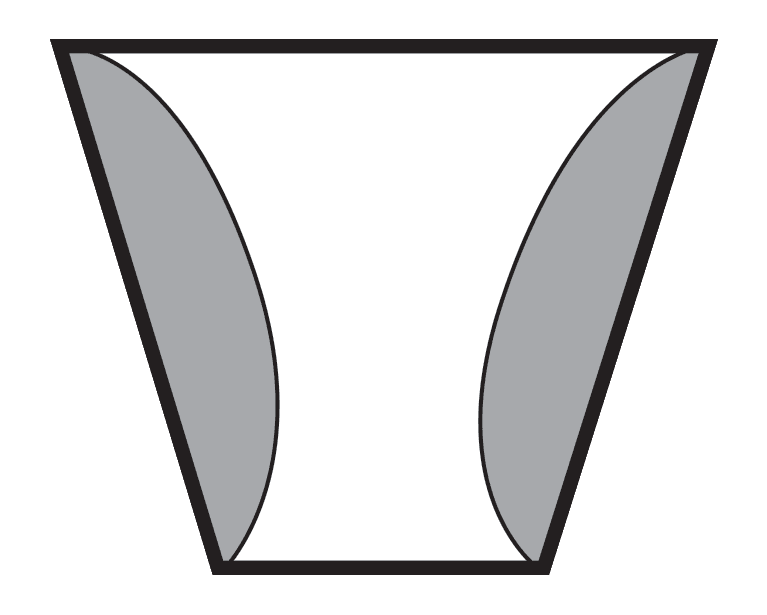

Damp/larger Size Product

Linear non-impacting models are excellent for larger sized dry product and damp materials where the extra working movement is required.

Bridging

Chute Solutions

Are you looking for a solution to a chute angle problem? Sometimes chutes are added after the plant is built. This can mean that the chute is at less than the optimum angle for product flow and the material needs assistance to move. Whatever your chute issues may be, our friendly and professional team will be more than happy to help. VSS have over 40 years’ experience providing vibrator solutions to this problem with electric, pneumatic and hydraulic vibrators.

For more information about chute solutions, call our friendly team today on 1800 300 877